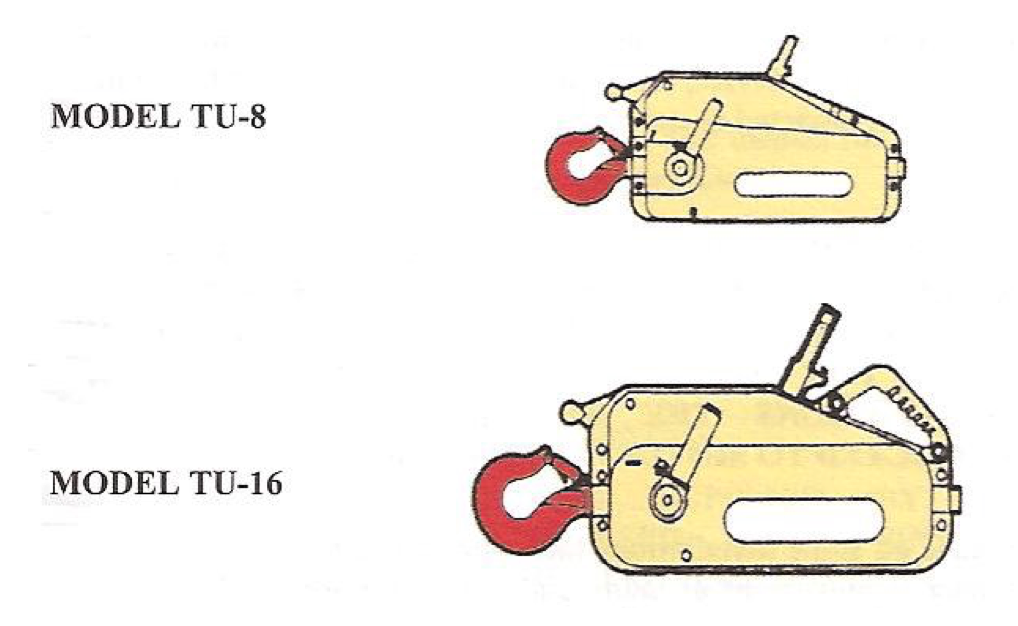

Wire Grip - Pull Lifting Machines (Tirfors)

These are lever operated machines which use a gripping action to haul a wire rope. They are self sustaining and may be used for both lifting and pulling applications. They may be used in conjunction with pulley blocks either to increase the mechanical advantage or to divert the line of pull. Don’t forget the resulting load imposed on the supporting structure.

The wire rope passes through the machine and can be stored on a special coiler separate from the machine. This makes them ideal for extremely high lifts or for pulling a long distance. They are frequently used for maintenance and construction work.

Safety

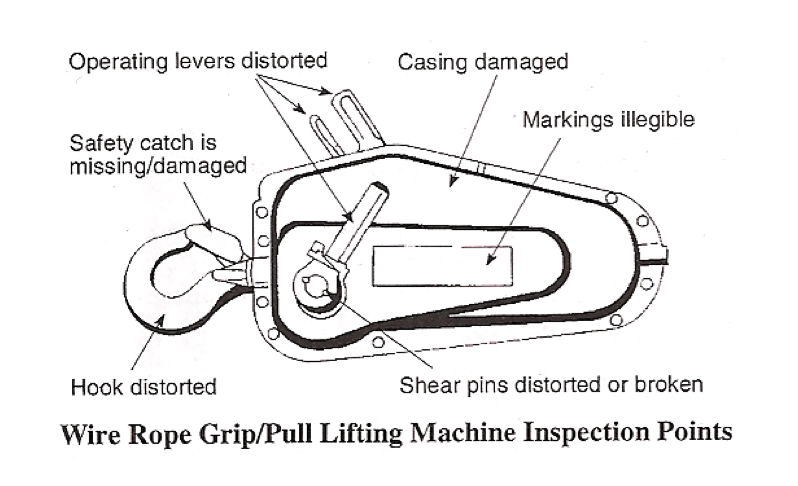

Al machines have a safety system in place and this is usually in the form of shear pin(s). In an overload situation one or more of the shear pins will break resulting in the machine from operating in a forward motion. It is still possible to operate the machine in a reverse mode, to enable the load to be lowered or the wire rope to be slackened off to release the machine. The shear pins are made of either brass or aluminum.

WARNING.

If the shear pin breaks never try and replace it with anything and try to continue with the operation.Various Types of Machines

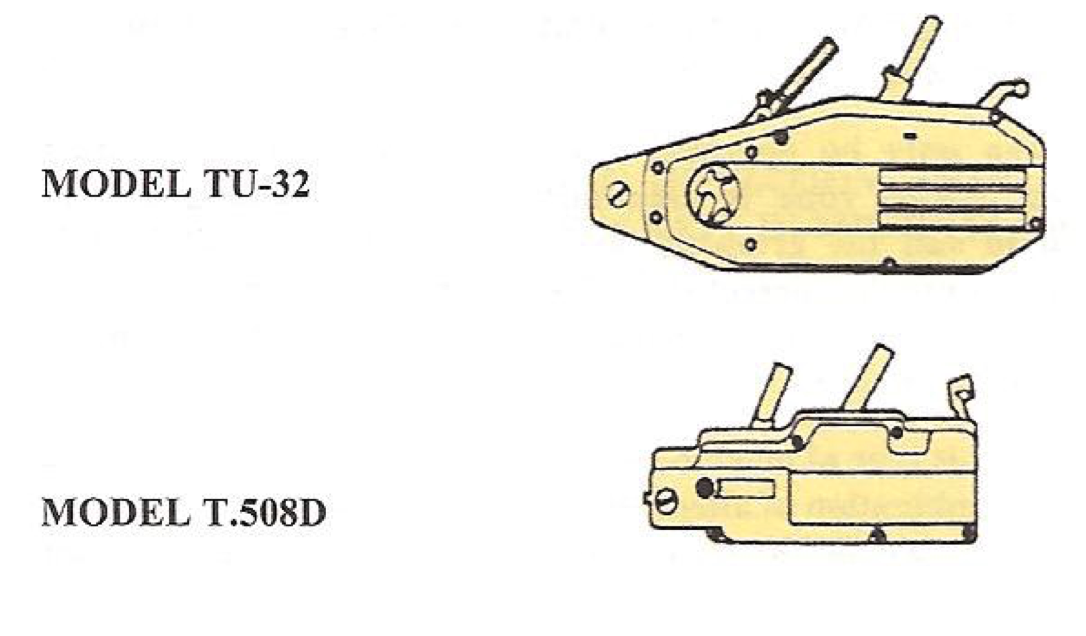

Location of the shear pins in the different types of machines

Location of the shear pins in the different types of machines

Inspection Of The Machines

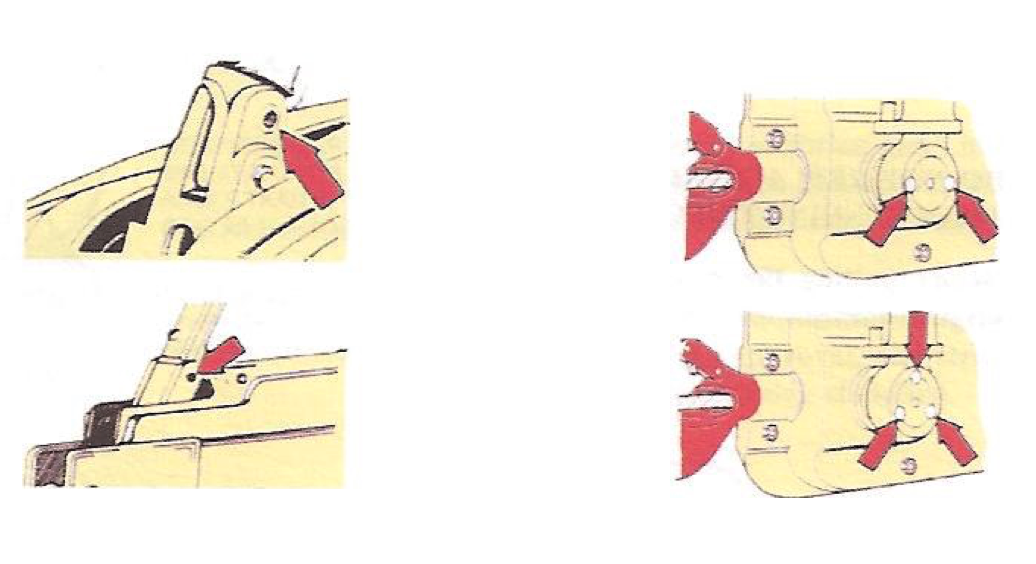

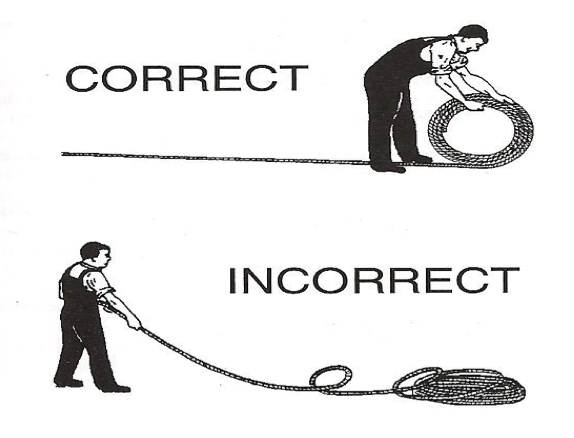

Correct and incorrect methods of uncoiling the wire rope if it is not on the special coiler.

The wire needs to be inspected along with the machine; the wire rope should be inspected as any other wire rope.

Maintenance

Follow the specific instructions for maintenance issued by the manufacturers. In particular keep the machine well lubricated. Lack of lubrication will result in a jerky movement or failure to operate. It is impossible to over lubricate grip/pull machines.

Example of SWL of Machines

| Lifting | Pulling |

|---|---|

| 800kg | 1200kg |

| 1600kg | 2400kg |

| 3200kg | 4850kg |

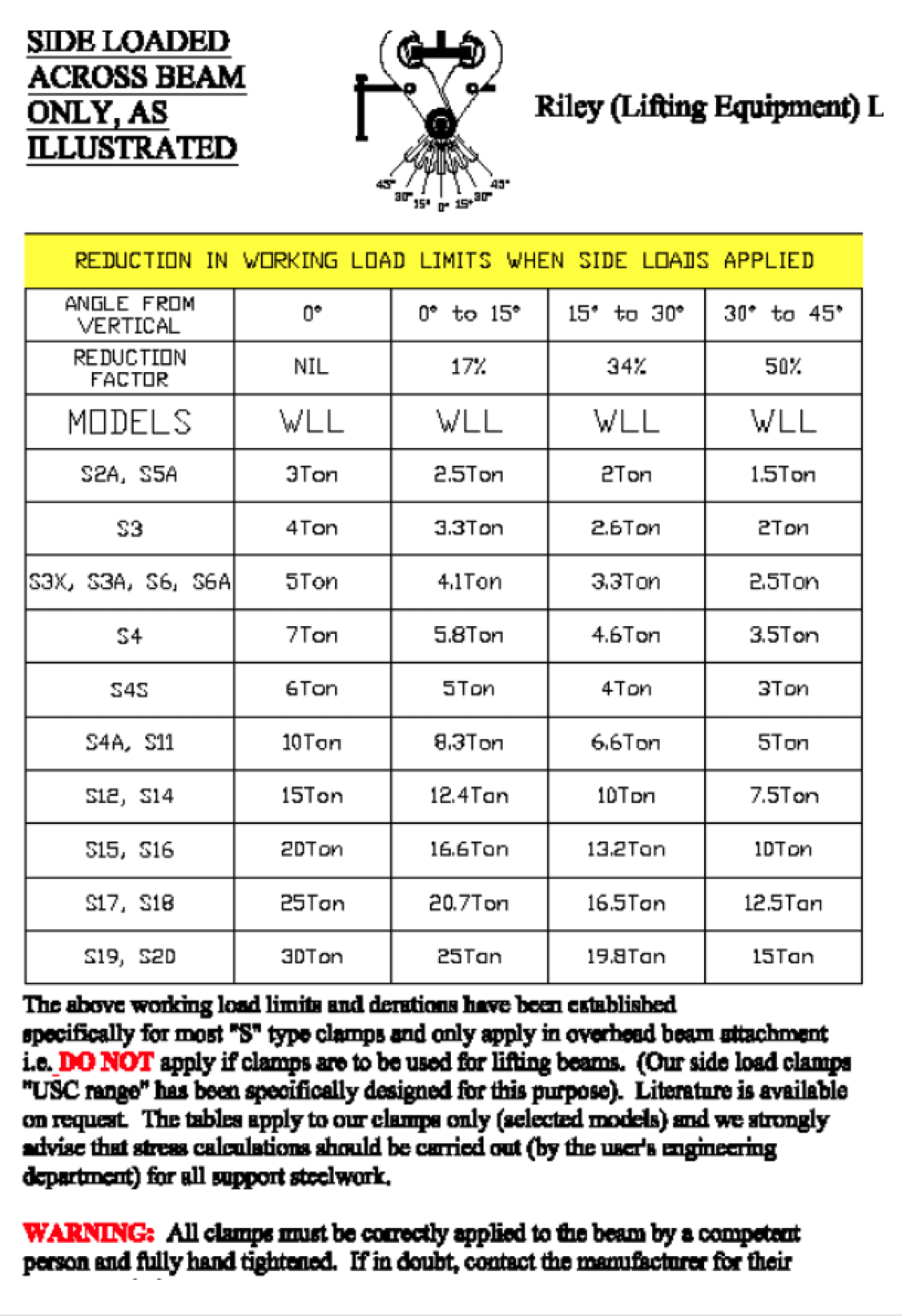

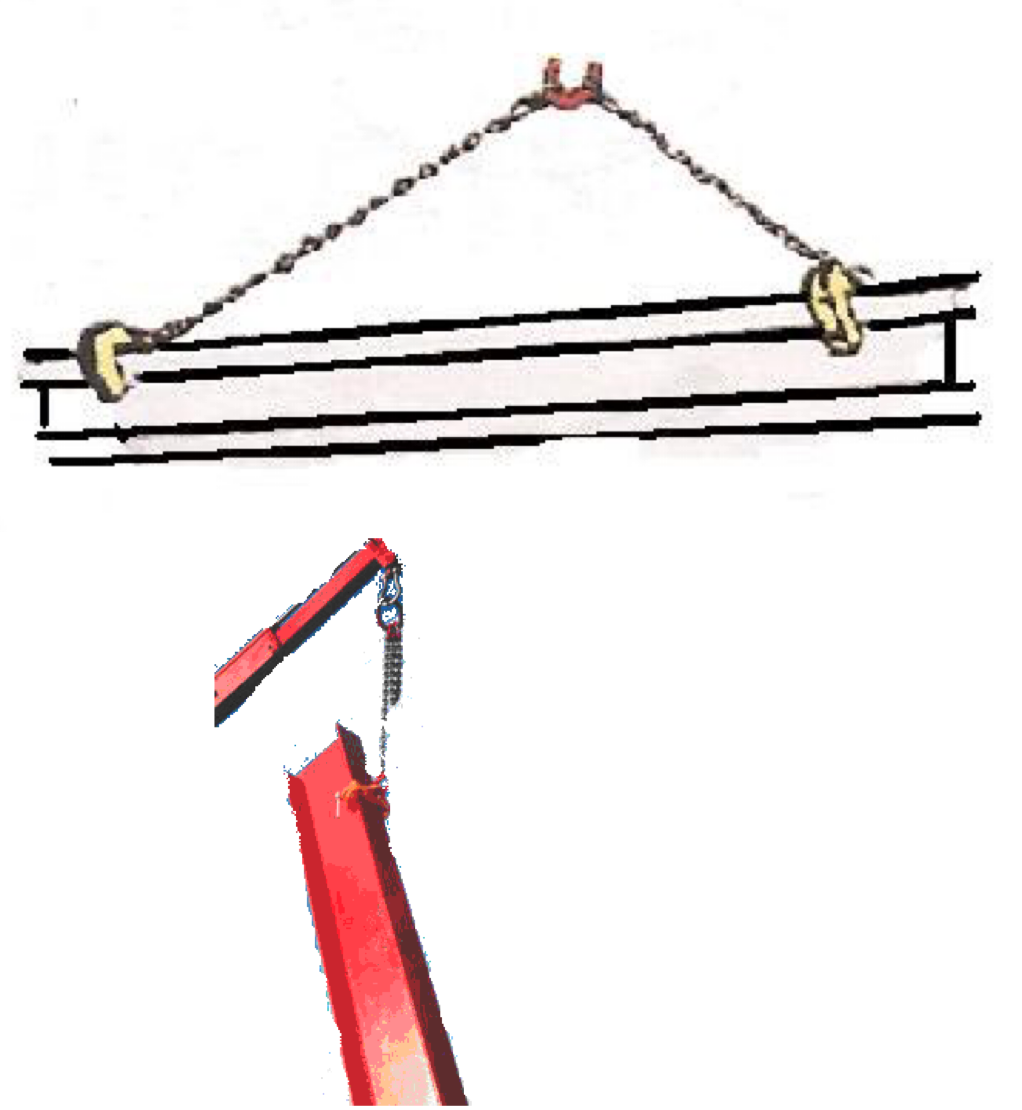

Riley Beam Clamps / Beam Trolleys

Beam clamps are primarily designed for vertical use and are rated at 0 degrees. We can however get beam clamps which are used at an angle, but they must be marked accordingly and then down rated to suit. The maximum angle that they can be used at is 45 degrees and down rated by 50% of the SWL.

Beam clamps stamped S1, S2 and S5 are only to be used in a vertical position.

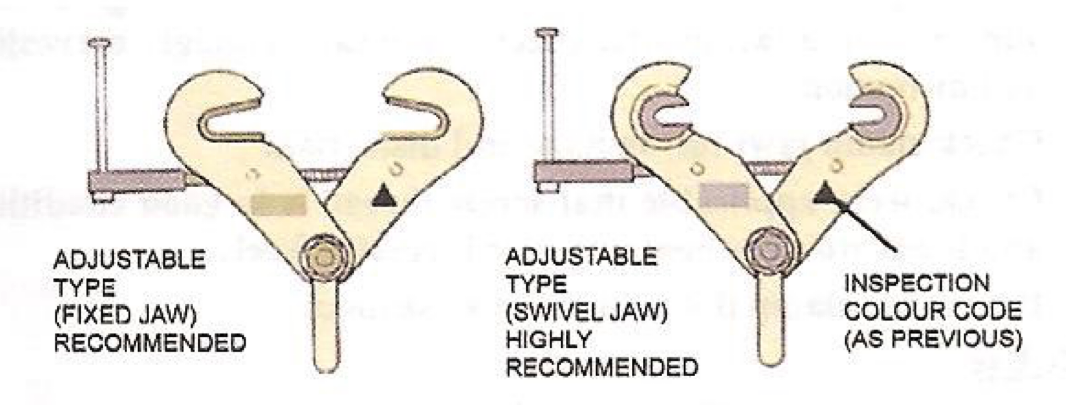

Types of Beam Clamp

Pre use Inspection of the clamps

The pre use checks should include the following:

- SWL, ID number

- Correct size for beam

- Check shackle body for wear

- Side plates for distortion, cracks

- Excessive play on hinge points

- Threaded bar for twisting or worn

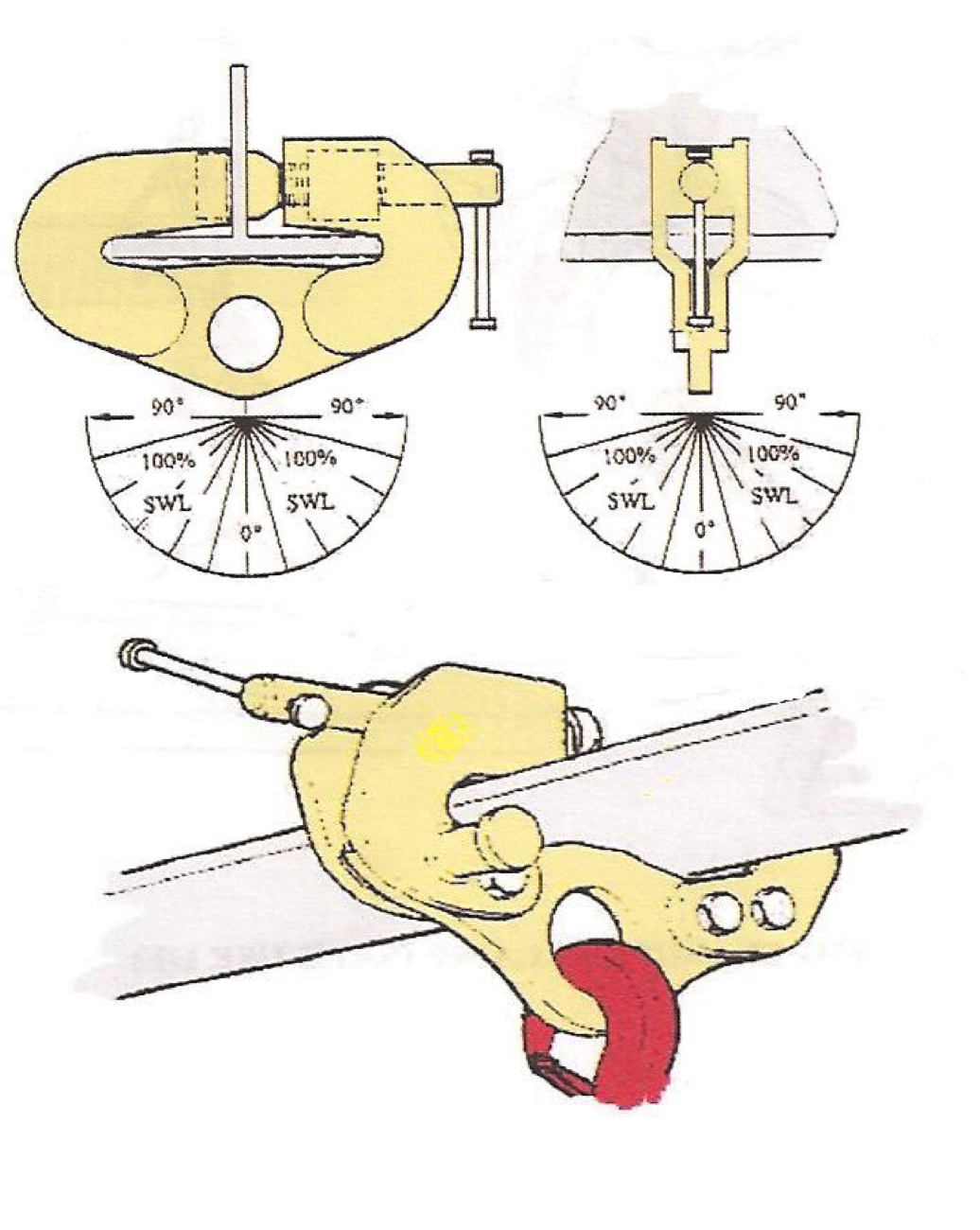

Riley Universal Super Clamp

This type of clamp the universal superclamp can be used in conjunction with cranes where the normal clamp cannot, this one can also be used up to an included angle of 90 degrees in any direction, it also has the advantage of low headroom anchor point.

Low headroom requirement

This type of clamp can also be used in pairs so can reduce the need for using spreader beams. Used in conjunction with a crane.